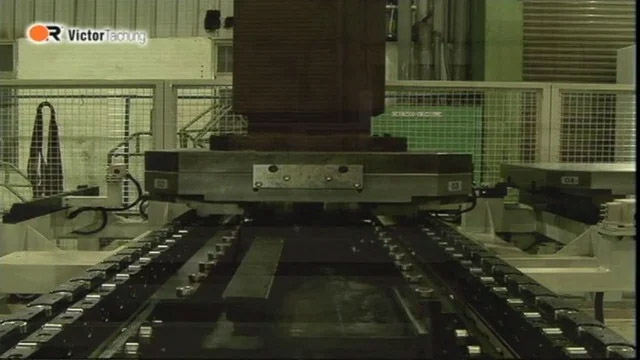

Horizontal Machining Center

Vcenter-H630HD/H1000

As with all Victor Taichung machine tools, Vcenter-H630/H1000 have been designed with the concept of reliability and stability foremost. Emphasis has been placed on continuous cutting ability in selecting machine structure and components. From the bed ribbing to machine assembly, Victor Taichung employs over 60 years experience in machine tool building to ensure machine down-time is kept to a minimum.

Features

Advanced design

Through the use of advanced CAD and CAE, our R&D laboratory makes computer simulations of the machine’s structure for deformation and vibration during operation, which can be later confirmed by computer aided testing. Areas of high stress concentration or excessive thermal growth are pinpointed on the drawing board, so they are eliminated at an early stage and optimum machine life can be guaranteed.

Specification

| ITEM | Unit | Vcenter-H630HD | Vcenter-H1000 | |

|---|---|---|---|---|

| CAPACITY | X axis travel | mm | 900 | 1350 |

| Y axis travel | mm | 800 | 1050 | |

| Z axis travel | mm | 710 | 1050 | |

| DISTANCE | Spindle nose to table center | mm | 200 - 910 | 220 - 1270 |

| Spindle center to table surface | mm | 0 - 800 | 0 - 1050 | |

| Max. machining area (W x L x H) | mm | 880 x ø1200 x 930 | ø1350 x 1350 | |

| WORKING TABLE | Table work area | mm | 630 x 630 | 1000 x 1000 |

| Max. table pallet | kg | 1200 | 2000 | |

| Surface configuration | M16 x P2.0 | M16 x P2.0 | ||

| Min. angle of rotation | deg | 1 (opt. 0.001 for CNC table) | 1 (opt. 0.001 for CNC table) | |

| Pallet exchange time | sec | 30 (chip-chip) | 45 (chip-chip) | |

| Pallet exchange type | Parallel | Parallel | ||

| Time to inde x 90° | sec | 5 (opt. 2 for CNC table) | 8 (opt. 4 for CNC table) | |

| Time to inde x 180° | sec | 7 (opt. 3 for CNC table) | 10 (opt. 5 for CNC table) | |

| SPINDLE | Spindle taper | BT 50 | BT 50 | |

| Spindle motor- cont/30min | Kw | 15/18.5 (opt. 18.5/22) |

18.5/22 | |

| Spindle speed | rpm | 4500 (opt. 6000) | 4500 | |

| Spindle bearing diameter | mm | 100 | 100 | |

| AXES FEED | Rapid feed rate - X / Y / Z | m/min | 24 / 24 /24 | 15/15/15 (opt. 20/20/15) |

| Axis feed motor - X/Y/Z | Kw | 7 / 9 / 7 | 9 / 9 / 9 | |

| Cutting feed rate by table | mm/min | 10000 | 10000 | |

| B axis feed motor | Kw | 1.6 (opt. 3 for CNC table) | 4 (opt. 7 for CNC table) | |

| X/Y/Z ball screw (dia. x pitch) | mm | ø50 x P10 | ø55 x P10 | |

| Boxway hordness | HRC 55 | HRC 55 | ||

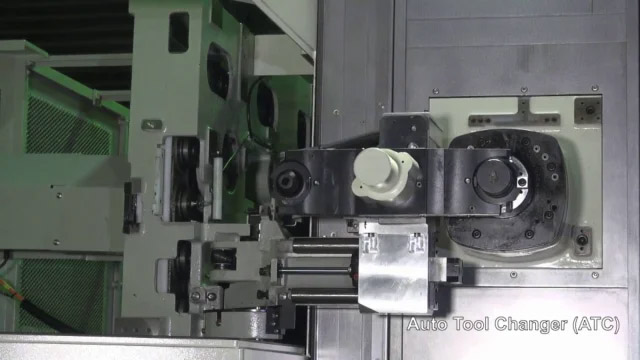

| ATC & Tools | Tool magazine capacity | 60 (opt. 90, 120) | 60 (opt. 90, 120) | |

| Tool selection | Fixed tool pot number | Fixed tool pot number | ||

| Max. tool dia. (without Adjacent tool) | mm | 110 (245) | 110 (245) | |

| Max. tool length | mm | 600 | 600 | |

| Max. tool weight | kg | 25 | 25 | |

| Tool exchange time | sec. | 13.8 (T-T), 15.6 (C-C) | 13.8 (T-T), 20.5 (C-C) | |

| Pull stud angle | deg. | 60° | 60° | |

| MACHINE | Standard CNC controller | 0i-MD (10.4”) | 0i-MD (10.4”) | |

| Power requirement | KVA | 40 (50 with CTS) | 54 (60 with CTS) | |

| Air pressure requirement | Kg/cm2 | 5.5 ~ 6.5 | 5.5 ~ 6.5 | |

| Coolant tank | L | 500 | 600 | |

| Chip disposal (with chip conveyor) | Left and front | Left and front | ||

| Machine height | mm | 3195 | 3950 | |

| Floor space requirement | mm | 3635 x 5250 | 4580 x 8400 | |

| Machine weight | kg | 18000 | 31420 |