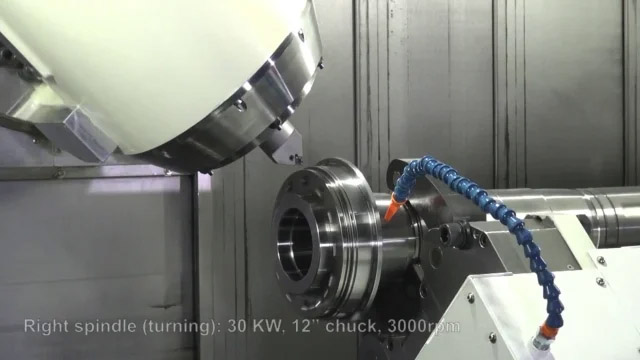

Multi-Tasking Turning Center

VMT-X360/X400

- Turning & Milling in one set-up

- Y-axis travel 420 mm (16.5")

- Max. turning dimension Ø720 x 2100 mm

- Turning spindle 3000 rpm / 30 KW with 12” chuck for Vmt-X360, or 2500 rpm / 30 kW with 15” chuck for Vmt-X400

- Milling spindle 12000 rpm / 22 KW

- with HSK-T63 / A63 tooling

- ATC-60 tools

Features

- Heavy cutting in entire Y-axis travel 420mm (16.5")

- Roller geared B-axis sivel head with curvic coupling enhance clamping rigidity for heavy cutting

- Twin built-in spindles and swivel head with built-in milling spindle implement 4+1 axis machining in one set-up

Victor Taichung is an industry expert in offering advanced multi-tasking machining solutions. Our multitasking turning centers and vertical machining centers are recognized as one of best machining centres in the whole world. If you have any machining question need to consult, welcome to your contact!

Specification

| Items | Unit | VMT-X360 | VMT-X400 | |

|---|---|---|---|---|

| Capacity | Swing over bed | mm | 1120 | 1120 |

| Between centers | mm | 2148 | 2148 | |

| Max. turning length | mm | 2100 | 2100 | |

| Max. turning diameter | mm | 720 (tool length 70mm) | 720 (tool length 70mm) | |

| Travels | X1-axis (upper tool spindle) | mm | 840 (+715/-125) | 840 (+715/-125) |

| Z1-axis (upper tool spindle) | mm | 2230 (130+2100) | 2230 (130+2100) | |

| Y-axis (upper tool spindle only) | mm | 420 (±210) | 420 (±210) | |

| B-axis | deg | 240 (-30~+210) | 240 (-30~+210) | |

| E-axis (tailstock / sub-spindle) | mm | 1960 | 1960 | |

| Axis feed | X1/Z1/Y/E/B-axis feed | m/min | 36/36/36/24/(30 rpm) | 36/36/36/24/(30 rpm) |

| X1/Z1/Y/E/B axis motor power | kW | 9 / 9 / 7 / 2.5 / 4 | 9 / 9 / 7 / 2.5 / 3 | |

| Ball screw dia. x pitch | mm | X1/Y: 45 x P16, Z1: 55 x P20 E: 45 x P16 |

X1: 45 x P16, Z1: 55 x P20 Y:45 x P16 E: 45 x P20 |

|

| Main spindle | 1st spindle nose (chuck) | inch | A2-11 (12”) | A2-11 (12”, opt. 15”, 18”) |

| 1st spindle speed | rpm | 3000 | 3000 | |

| 1st spindle motor power (cont./30 min/15%) | kW | 22/26/30 (high winding) | 22/26/30 (high winding) | |

| Spindle bore | mm | 116 | 116 | |

| Bearing inside diameter | mm | 160 | 160 | |

| Bar capacity | mm | 91 (opt. 106) | 91 (opt. 105) | |

| Subspindle (optional) | 2nd spindle nose (chuck) | inch | A2-11 (12”) | A2-11 (12”, opt. 15”, 18”) |

| 2nd spindle speed | rpm | 3000 | 3000 | |

| 2nd spindle motor power (cont./30 min/15%) | kW | 22/26/30 (high winding) | 22/26/30 (high winding) | |

| Spindle bore | mm | 116 | 116 | |

| Bearing inside diameter | mm | 160 | 160 | |

| Bar capacity | mm | 91(opt. 106) | 91 (opt. 105) | |

| Upper milling spindle (B-axis milling head) | Turret type | rpm | Milling head with ATC | Milling head with ATC |

| Continuous indexing resolution: | deg. | 0.001 (by roller gear) | 0.001 (by roller gear) | |

| Max. speed | rpm | 12000 | 12000 | |

| Milling motor power (cont./30min/25%) | kW | 15/18.5/22 (high winding) | 15/18.5/22 (high winding) 26/30/37 (opt.) |

|

| ATC & tool magazine | Tool specification | - | HSK-T63 | HSK-T63 |

| Tool capacity | - | 60 | 60 | |

| Tool selection | - | Fixed tool pot number | Fixed tool pot number | |

| Max. tool diameter (w/t adjacent tool) | mm | 100 (150) | 100 (150) | |

| Max. tool length | mm | 400 | 400 | |

| Max. tool weight | kg | 7 | 7 | |

| Tool exchange time | sec | 3.3 (T-T), 8.5 (C-C) | 2.2 (T-T), 7.2 (C-C) | |

| Tailstock | Quill diameter | mm | NA (digital) | NA (digital) |

| Quill stroke | mm | NA (digital) | NA (digital) | |

| Quill taper | MT-5 (live) | MT-4 (live) | ||

| Machine | Controller | Fanuc | 0i-TF Plus (15”, type 0) | 0i-TF Plus (15”, type 0) |

| Tank capacity | L. | 750 | 750 | |

| Floor requirement (incl. chip conveyor) | mm | 7945 x 3316 x 3320 | 7945 x 3316 x 3320 | |

| Power requirement | kVA | 66 | 66 (90) | |

| Net weight | kg | 23500 | 23500 | |

Standard accessories:

- Fanuc 0i-TF PLUS (15", type 0) control with iHMI + AICC + MGI

- Hydraulic chuck with soft jaws

- Chip conveyor with cart

- Automatic Tool Presetter (Renishaw®) for milling spindle

- Coolant flush to the bottom of Z-axis covers by Walrus pump TPHK 4T4-4 (4 bars/60Hz)

- Coolant ring around milling spindle with high pressure coolant (4 bars/60Hz) by Walrus® pump TPHK 4T4-4)

- Coolants through milling spindle (7 bars/60Hz) for high pressure turning

- Digital tailstock

- LHL (Lube Hybrid Lubrication) system

- Spindle oil cooler

- Fully enclosed splash guarding

- Hand-wheel (Pulse generator)

- 3 step warning light

- Handy air gun

Optional accessories:

- 2nd spindle (right spindle)

- KITAGAWA® hydraulic chuck

- Hard jaws

- Coolant Through Spindle (CTS)

- Steady rest

- High pressure coolants

- Bar feeder interface

- Robotic parts catcher

- Hand-wheel (remote MPG)

- Air blow system

- Auto door

- Fanuc manuals

- Oil skimmer (not required because of LHL lube system.)

- Fanuc 31i-B5 Plus control for 5-axis simultaneous machining

- Test bar for accuracy calibration

- Coolant gun